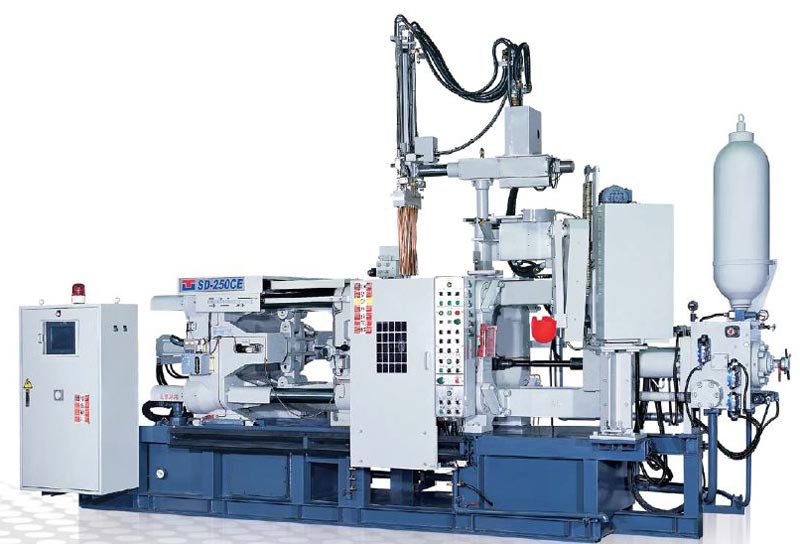

PDC Machines

Equipped with ultra-modern, high-precision Pressure die casting machines with a locking force ranging from 100T to 200T, We have the highest capabilities to produce alloy parts with high precision and strength, with a quick turnaround time compared to other manufacturers.

What make us the best

- Our PDC machines hold a melting capacity of 350 kg/hour

- Equipped with more than 300 die molds for various industries including aerospace and defense

- Processing more than 6 types of alloys

- Annual processing capacity of 1,500 tons

- Daily production of more than 17,000 components

- Online inception patrol to manage and monitor metal quality

- Advanced degassing unit to improve the reliability of the metal

Machining

Machine shop

To meet our customers’ evolving needs and demand, SKYFAST is equipped with the latest CNC Machines, VMC, SPM (Special Purpose Machine) in our machine shop. This enables us to provide machining for die casting parts at high precision in a short turnaround time.

CNC Machine

With over 8+ CNC machines, we strive to develop components with exceptional dimensional accuracy. Our CNC chuck diameter ranges from 135,165 to 200m. Besides our advanced automation, CNC machines assure high productivity and quality.

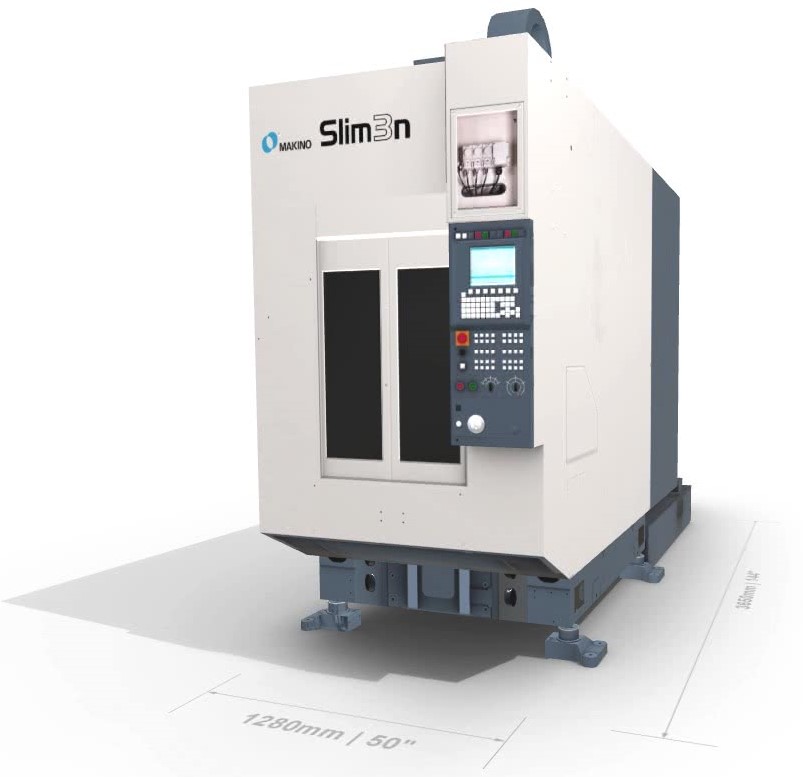

VMC

Our VMC machine capacity goes on par with the best in the industry. SKYFAST is equipped with the world's best VM machine. These machines are capable of taping and drilling die casting components with high precision.

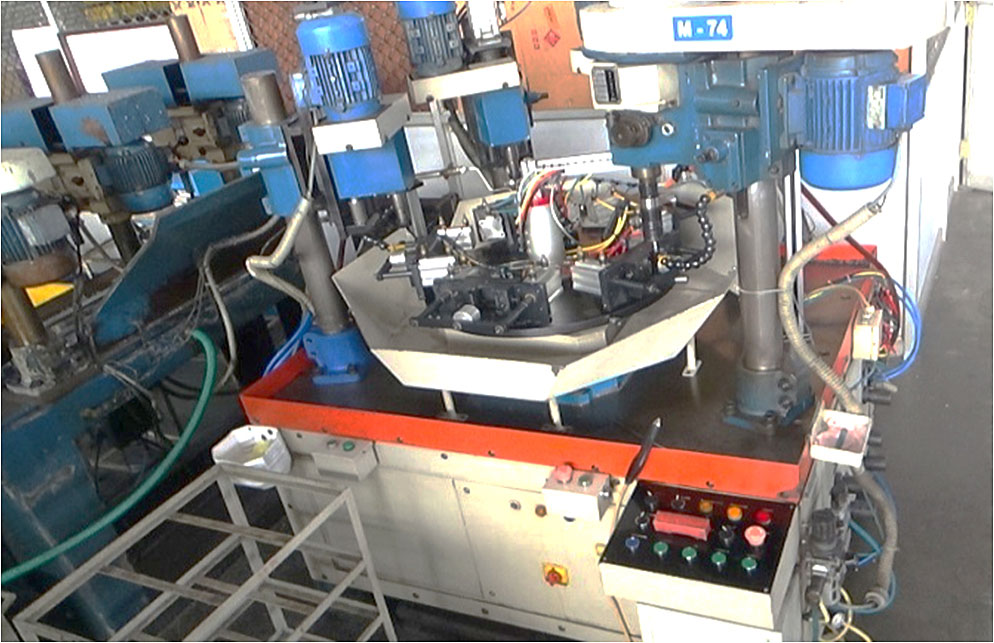

SPM

We are housed with a wide range of Special Purpose Machines like SPM rotary table, Auto feeder drill (1 mm), to reduce production time and increase the operational efficiency in order to meet the customer requirements on time.

An effective and rigorous manual Quality Assurance system is enabled to ensure that only the right quality product reaches the customers. Right from the die casting stage, following right through to the alloying, pouring, fettling, machining and painting processes, each stage of casting is monitored carefully by our trained and skilled employees.

Our aim is to instill stringent die casting process controls, as well as strict inspection methods, and maintain the highest standard of quality throughout the lifetime of the product. Our processes and systems are certified to ISO standards.

To give our customer a one-stop solution, SKYFAST offers all kinds of surface finish options that enhance the component’s mechanical and aesthetic properties. We are capable of delivering fully-finished components to any customized surface finish as per client requirement. We provide shot blasting, vibro finish and powder coating.

Our sophisticated painting facility is housed with a pre-treatment plant and Pad printing machine which allows us to improve the aesthetics of the die casting products.

Features

- Chrome-free pre-treatment system

- An environment-friendly, integrated paint facility

- Waterfall paint-booth mitigates dust emission

- Hot bath phosphating

- Pad printing machine

- Vaccuming

- Short blasting